Hydrogen is the simplest and most abundant element in the universe, consisting of just one proton and one electron. Hydrogen makes up about 75% of the elemental mass of the universe and is a primary component of stars.

Here on planet Earth, hydrogen is predominantly found in water (H2O), organic compounds and a component of hydrocarbons such as natural gas, oil, and coal.

Under normal conditions, hydrogen is a colourless, odourless, and tasteless gas. It exists as diatomic molecules (H2), meaning two hydrogen atoms bond together to form a single molecule.

Hydrogen is highly reactive and readily forms compounds with most elements. Its high reactivity is why it is rarely found in its free form on Earth and needs to be processed to extract hydrogen as a gas.

Hydrogen is a fundamental element with wide-ranging applications, especially as a clean energy carrier. Its potential to support the transition to a low-carbon economy makes it a critical component of future energy systems.

In 2023, global hydrogen production reached approximately 95 million tonnes. This production is primarily dominated by traditional methods using fossil fuels, such as steam methane reforming (SMR), which accounts for most hydrogen output. However, the production of low-emission or green hydrogen, which is generated through electrolysis using renewable energy, is growing as efforts to decarbonise various sectors intensify.

Produced cleanly Hydrogen could become a significant part of the solution to lower emissions and reach the global Net Zero targets. Hydrogen is widely used in industry to produce chemicals and materials and can be used for electricity production, transportation and as gas for heating.

PRODUCTION AND USES

INDUSTRIAL PRODUCTION: Pure hydrogen is produced mainly through methods such as steam methane reforming (SMR), electrolysis of water, and coal gasification.

STEAM METHANE REFORMING (SMR)

The most common method, involving the reaction of methane with water to produce hydrogen and carbon dioxide. SMR is used in the production of Ammonia, Methanol, Petroleum refining, Syngas (Synthetic fuels) and power generation from SMR produced hydrogen for fuel-cells.

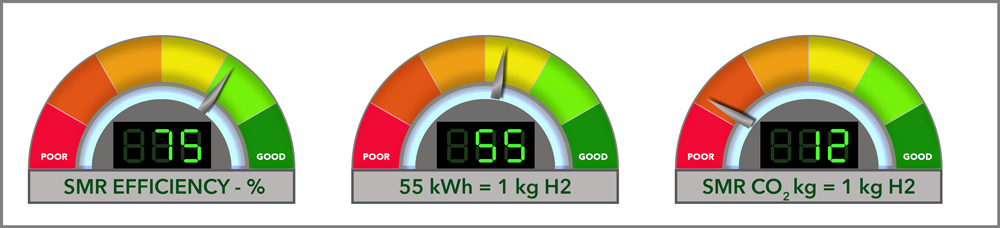

SMR is an energy-intensive process but currently remains the most economical method for large-scale hydrogen production. Significant improvement in the production efficiency and integrate carbon capture and storage (CCS) technologies are crucial for reducing its environmental impact and supporting the transition to cleaner hydrogen production methods.

According to McKinsey & Company, the overall thermal efficiency of SMR typically ranges between 65% and 75%. This means that 65-75% of the energy content in the methane is converted into hydrogen, while the remainder is lost as heat or used within the process itself.

There is a description of the SMR & CCS process here.

ELECTROLYSIS:

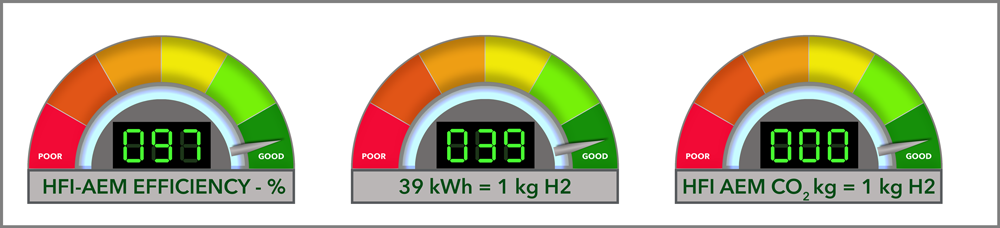

Uses electricity to split water into hydrogen and oxygen, with potential for producing green hydrogen if renewable energy is used. Green hydrogen is produced when 100% renewable energy, such as the HFI Energy System, is used to provide the DC electricity for electrolysis. Electrolysis uses more energy to create the hydrogen than the hydrogen provides, this is a reason why renewable energy is key to the success of Green Hydrogen.

Approximately 9 litres of water is required to produce 1 kg of hydrogen. Unlike with the SMR and CCS processes, the production of green hydrogen does not produce and carbon emissions.

ENERGY CARRIER: Hydrogen can be used in fuel cells to generate electricity, emitting only water vapour as a byproduct, making it a clean energy source. Each kilogram of hydrogen used in a fuel cell generates 9 litres of pure water, closely in line with the required amount of water required to make a kilogram (kg) of hydrogen with electrolysis.

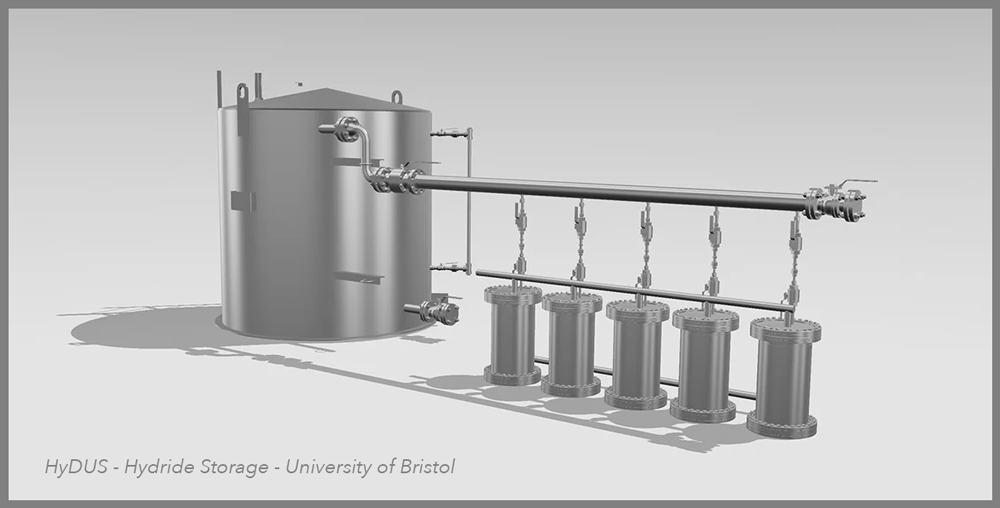

Hydrogen can be stored in a variety of ways and to provide electricity or gas on-demand when the demand requires it. Hydrogen storage options include as a compressed gas, as liquid hydrogen, Ammonia and as a hydride powered.

HFI offers a hydride solution that can be used for static storage of large quantities of hydrogen or for transportation such as trucks, buses and heavy equipment.

Hydrogen can additionally be used to dilute natural gas for heating to reduce the carbon emissions.

INDUSTRY: Essential in the production of ammonia for fertilizers, refining petroleum, and in the chemical industry. Hydrogen is increasingly being used in the production of synthetic fuels that can be tailored to replace conventional petrol (gasoline), diesel, and jet fuels with a carbon neutral alternative.

Hydrogen is increasingly being explored as a reducing agent in the steel industry. In the Direct Reduction of Iron Ore process, hydrogen can be used to reduce iron ore to iron, producing water vapor instead of CO₂, which makes it a cleaner alternative to traditional methods using coal or natural gas.

The production of semiconductors and electronics uses hydrogen to create a reducing atmosphere, clean surfaces, and as a carrier gas in chemical vapor deposition (CVD) processes.

In the process of manufacturing glass, Hydrogen is used in the float glass process, where it helps to create the correct atmosphere in the production of flat glass, which is used in windows, mirrors, and other applications.

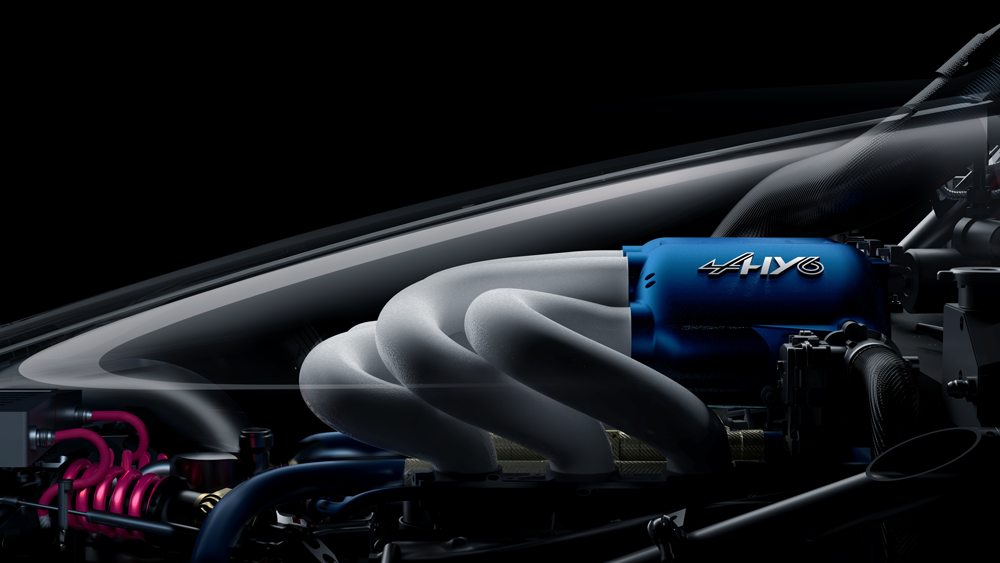

Indirectly, hydrogen is used in the production of materials such as nylon using Ammonia that is made from the use of hydrogen. TRANSPORTATION: Hydrogen fuel cell vehicles (FCVs) are an emerging technology, offering longer ranges and faster refuelling compared to battery electric vehicles. The development of internal combustion engines (ICE) powered by hydrogen in place of petrol (gas), or diesel has accelerated with Toyota and JCB leading the way in their sectors. Hydrogen is under development by companies such as Airbus for aviation and is considered an option for shipping.

FACTS & FIGURES ABOUT HYDROGEN

Hydrogen is a versatile and clean energy carrier with a wide range of applications. Here are some key facts and figures that highlight its importance and potential:

GLOBAL HYDROGEN PRODUCTION

TOTAL PRODUCTION: As of 2023, global hydrogen production was approximately 94 million tonnes (Mt). Approximately 55%-60% of the production was used to create ammonia, 30%-35% for petrochemical refining processes and 8%-10% for methanol production.

PRODUCTION METHODS:

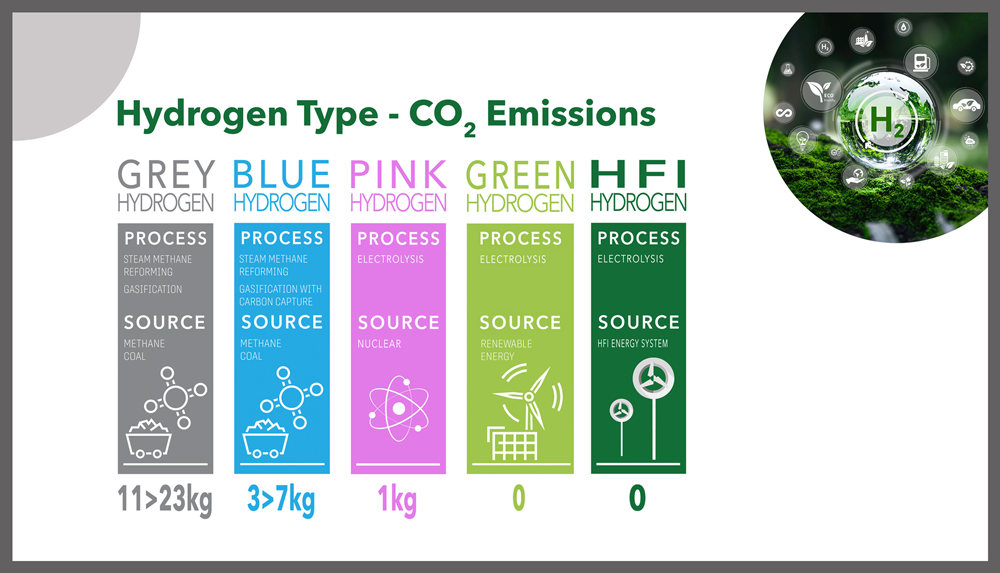

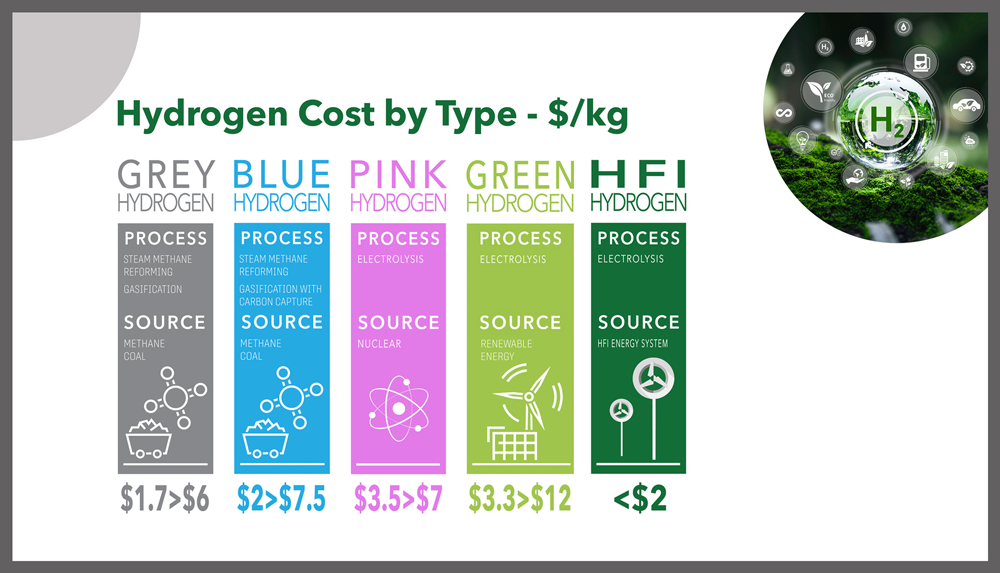

COST OF HYDROGEN PRODUCTION

EFFICIENCY AND USAGE

FUEL CELL EFFICIENCY: Hydrogen fuel cells have an efficiency of 50% to 60%, converting hydrogen into electricity.

The efficiency can be as high as 85% in static installations with the combined use of the heat generated by the fuel cell.

APPLICATIONS:

ENVIRONMENTAL IMPACT

EMISSION REDUCTION: Green hydrogen has the potential to reduce global CO2 emissions significantly, especially in hard-to-abate sectors like steel, cement, and heavy transportation.

ENERGY DENSITY: Hydrogen has a high energy density, with about 120 megajoules per kilogram (MJ/kg), making it an efficient energy carrier compared to batteries.

MARKET GROWTH AND INVESTMENTS

INVESTMENT: Over $500 billion in hydrogen projects and infrastructure investments are planned by 2030, with significant contributions from Europe, North America, and Asia.

POLICY SUPPORT: Governments worldwide are introducing policies and incentives to support hydrogen production and adoption, such as the EU’s Important Projects of Common European Interest (IPCEI) and the US Hydrogen Production Tax Credit.

IMPORTANCE IN ENERGY TRANSITION

CLEAN ENERGY POTENTIAL: Hydrogen can play a significant role in reducing greenhouse gas emissions, especially if produced through renewable means. It is a versatile energy carrier that can store and transport energy, thus supporting the integration of renewable energy sources. Green hydrogen is an essential piece of the clean energy mix that will be required to achieve the Net Zero targets set for globally for 2030 and 2050. According to IRENA (International Renewable Energy Agency), green hydrogen is to account for 14% of final energy consumption by 2050 and to abate 12% of emissions.

DECARBONISATION: Key to decarbonising sectors that are difficult to electrify, such as heavy industry, shipping, and aviation.

To achieve this scenario will require scaling up electrolyser capacity from 1 gigawatt (GW) at the beginning of 2023 to 5,722 GW by 2050, growth unlike any other emerging market.

The demand for green hydrogen is global and the leading industry sectors are heavy industry such as steel production, chemicals and mining and transportation and power generation as a stored renewable energy to provide grid stability or off-grid electricity supply.

As of 2024 the cost of producing green hydrogen per kilogram (LCOH) according to the Hydrogen Council and McKinsey & Company ranges from $4.50 to $6.50. The high production cost of green hydrogen is due to the need for high levels of renewable energy and the capital and operational cost of electrolysers.

HFI is working hard to reduce the cost of Green Hydrogen production and aims to reduce the cost to under $2 kg/H2 by 2025.

WHY USE GREEN HYDROGEN FOR ELECTRICITY, GAS, AND INDUSTRY?

Green hydrogen, produced through the electrolysis of water using renewable energy sources, is a versatile and clean energy carrier. Here’s why it is crucial for electricity, gas, and industry: ELECTRICITY GENERATION AND STORAGE

GAS SUPPLY

INDUSTRIAL APPLICATIONS

IMPORTANCE OF GREEN HYDROGEN FOR GLOBAL NET ZERO TARGETS

Green hydrogen plays a pivotal role in achieving global net-zero targets due to its ability to decarbonize multiple sectors: REDUCTION OF GREENHOUSE GAS EMISSIONS

ENERGY SECURITY AND INDEPENDENCE

INCREASING THE USE OF HYDROGEN

To increase the adoption of green hydrogen, several strategies can be implemented: POLICY AND REGULATORY SUPPORT

INFRASTRUCTURE DEVELOPMENT

RESEARCH & DEVELOPMENT

Green hydrogen is a cornerstone for achieving global net-zero targets, offering a versatile and sustainable solution for decarbonising electricity, gas, and industry. By leveraging policy support, infrastructure development, and technological innovation, we can accelerate the transition to a hydrogen-based economy, ensuring a cleaner and more sustainable future.

Hydrogen is poised to play a crucial role in the global transition to a low-carbon economy. With ongoing investments and technological advancements, hydrogen production costs are expected to decrease, making it a more viable and competitive alternative to fossil fuels. Its ability to decarbonise multiple sectors and provide energy storage solutions makes it an essential component of future energy systems. |