HFI AEM ELECTROLYSER: REVOLUTIONISING HYDROGEN PRODUCTION The production of green hydrogen is crucial for achieving the Paris Agreement’s climate goals, as it provides a versatile and scalable solution for decarbonising sectors that are difficult to electrify, such as heavy industry, transportation, and long-term energy storage. Green hydrogen, produced through electrolysis using renewable energy, generates zero greenhouse gas emissions when used, making it essential for reducing emissions to meet international climate targets.

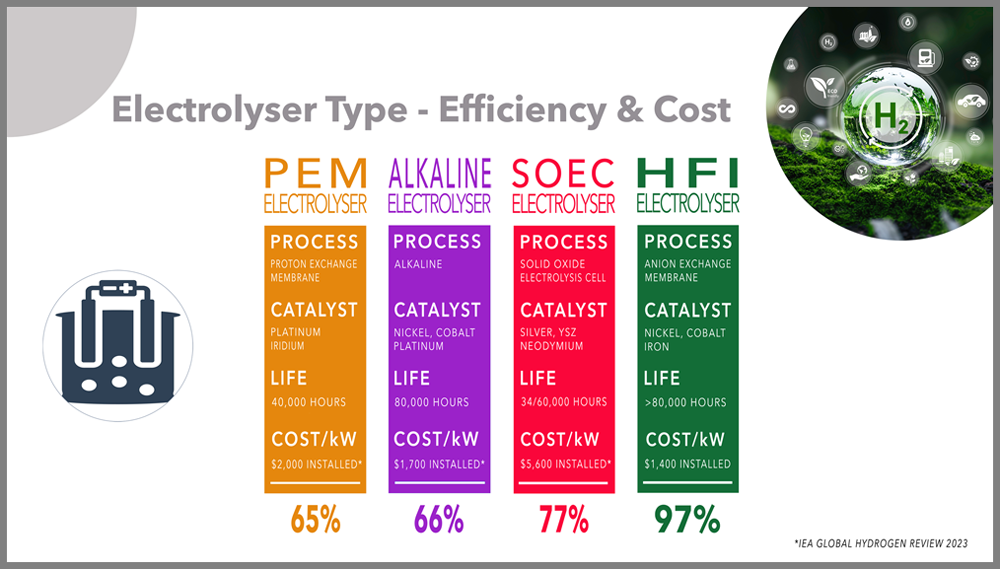

Electrolysers, which are devices that split water into hydrogen and oxygen, are key to producing green hydrogen. While various types of electrolysers exist, each with its own advantages and disadvantages, they all enable the conversion of surplus renewable energy into hydrogen. This hydrogen can be stored and used on demand, helping to stabilise the grid and decarbonise sectors that are hard to electrify directly.

Explore the different types of electrolyser technologies by clicking here.

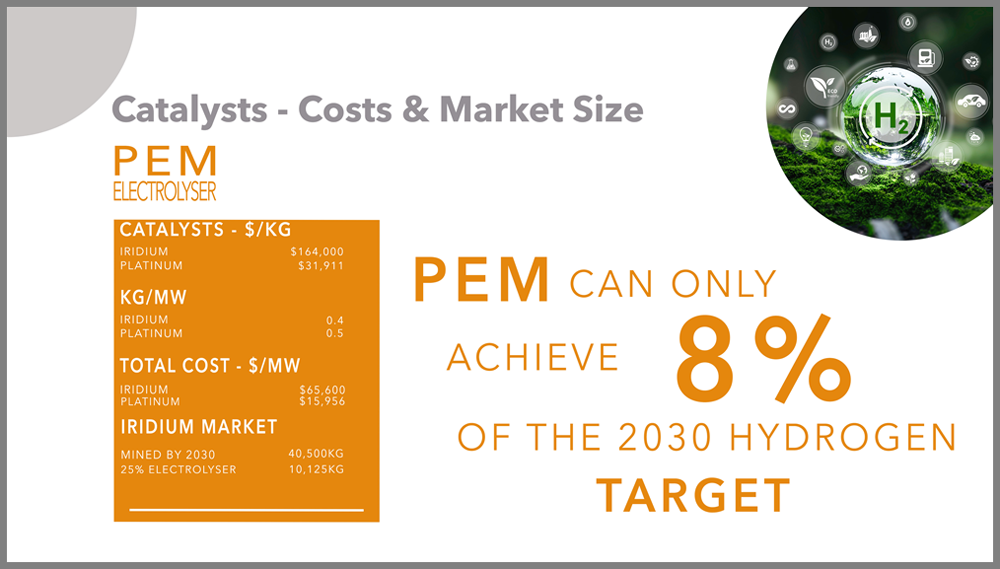

After extensive research into green hydrogen production, HFI chose to develop its own Anion Exchange Membrane Water Electrolyser (AEMWE) instead of following the industry trend toward Proton Exchange Membrane (PEM) electrolysers. The decision was partly driven by the recognition that PEM technology heavily relies on Platinum Group Metals (PGMs) like iridium and platinum for catalysts, which are both scarce and prohibitively expensive.

The extreme scarcity of iridium presents a major challenge to the scalability of PEM electrolysers, severely limiting their potential to be a significant player in the electrolyser market. A single megawatt (MW) of PEM electrolyser capacity requires approximately 0.4 kg of iridium. With iridium currently priced at $164,000 per kg (as of September 2024), the financial burden of using PGM materials is substantial. More critically, to achieve the global target of 233 GW of electrolysis capacity by 2030, set by the Paris Agreement, an estimated 94 tonnes of iridium would be needed if PEM technology were the primary choice. However, global iridium production is only about 8 tonnes per year, resulting in a total supply of merely 48 tonnes by 2030, far below what is necessary.

Iridium is not only 40 times rarer than gold but also in high demand across various sectors, including automotive, medical, petroleum, and space exploration. Even if the electrolyser industry were allocated up to 1.5 tonnes of iridium annually, it would still fall drastically short of the 94 tonnes required to meet PEM production demands. In fact, even if the entire annual global production of iridium were dedicated to PEM electrolysers, it would only satisfy about 8% of the projected demand. This stark reality underscores the critical limitations of relying on PEM technology for large-scale hydrogen production and highlights the need for alternative technologies that do not depend on such rare and expensive materials.

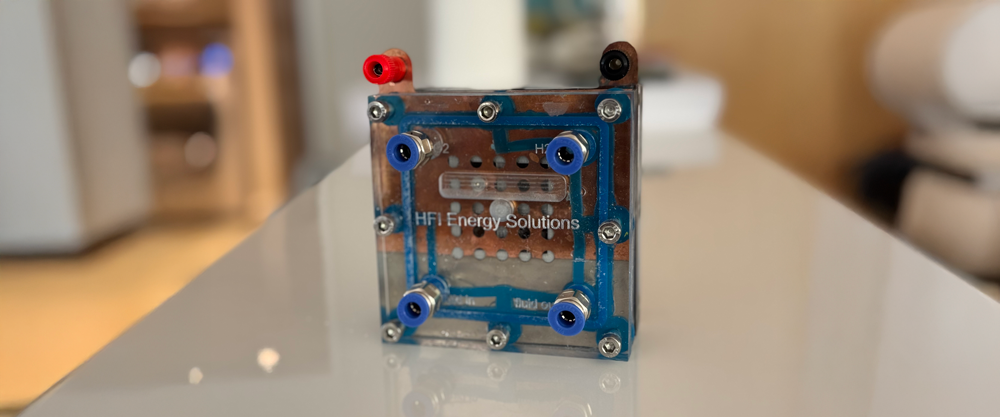

Recognising these constraints, HFI opted to develop an electrolyser using more abundant and sustainable materials to ensure the scalability of green hydrogen production and to help meet Net-Zero targets. The HFI zero-gap Anion Exchange Membrane Water Electrolyser (AEMWE) represents a significant innovation in hydrogen production technology. Unlike PEM electrolysers, the AEMWE does not require any PGMs, making it a more cost-effective and sustainable choice for large-scale deployment.

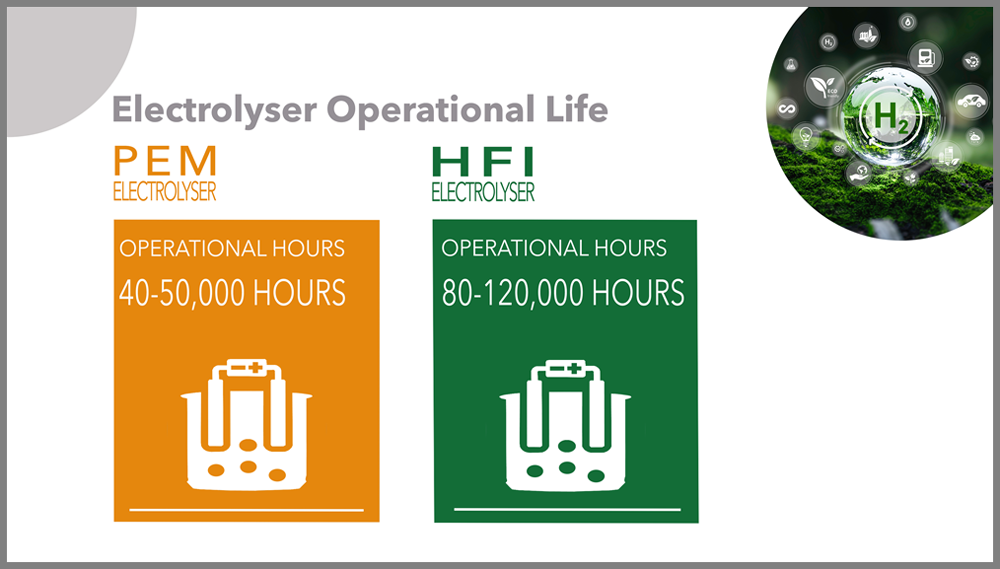

Developed in California, USA, the HFI AEMWE is designed to work efficiently with variable energy sources, such as wind and solar, without compromising performance. The electrolyser's design also emphasises reducing downtime and enhancing the ability to perform routine maintenance without halting hydrogen production, ensuring greater hydrogen output over the system's lifetime at a lower cost.

By choosing to innovate with the AEMWE, HFI is not only advancing the field of hydrogen production but also providing a viable solution to the material limitations that threaten the scalability of other electrolyser technologies.

KEY ADVANTAGES OF THE HFI AEM ELECTROLYSER

Exceptional Efficiency: The HFI AEM electrolyser boasts an impressive cell efficiency of 97%, far exceeding the 80-85% efficiency typically achieved by conventional electrolysers. This means that more hydrogen can be produced using less energy, making the HFI system an ideal choice for green hydrogen production.

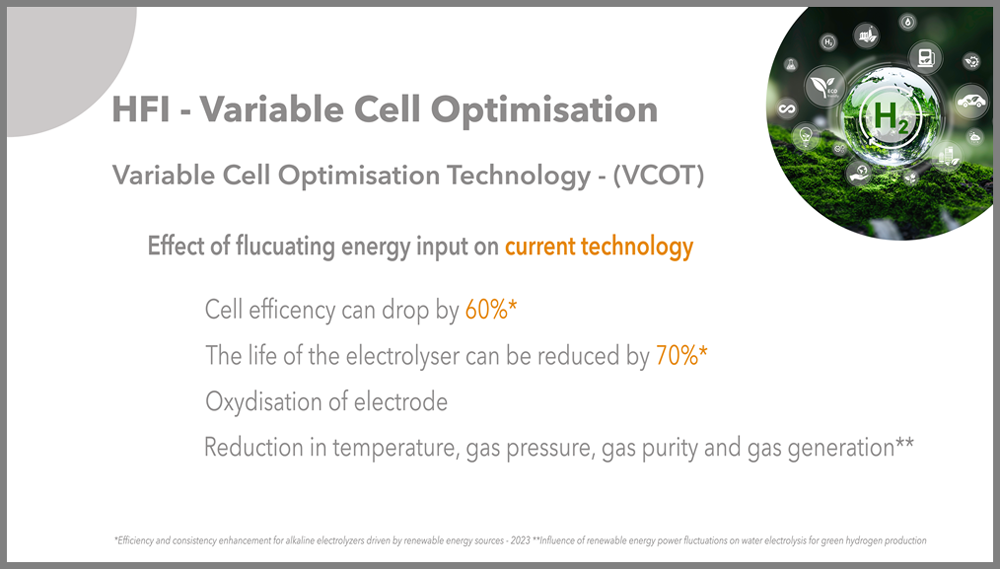

Compatibility with Renewable Energy: One of the standout features of the HFI electrolyser is its ability to operate efficiently under variable energy inputs, such as those from wind or solar power. Traditional electrolysers often suffer from reduced efficiency and increased degradation when faced with fluctuating energy supplies, which can significantly shorten their lifespan. In contrast, the HFI system is specifically designed to handle these fluctuations without compromising performance or durability.

Cost-Effective Design: The HFI electrolyser is designed to be significantly cheaper than Proton Exchange Membrane (PEM) electrolysers, with a target cost of around $800 per kilowatt—approximately 50% less than PEM systems, which can range from $1,200 to $2,000 per kilowatt. This cost reduction is achieved by eliminating the need for expensive Platinum Group Metals (PGMs) like platinum and iridium, which are essential components in PEM electrolysers. Instead, the HFI system uses more abundant and affordable catalysts, making it a more sustainable and scalable solution.

Longevity and Maintenance: The HFI AEM electrolyser offers a unique maintenance advantage: individual cells can be replaced without shutting down the entire system. This feature not only ensures continuous hydrogen production but also reduces operational downtime and maintenance costs. Furthermore, the system’s design optimises operational parameters to extend the life of the cells, further enhancing its cost-effectiveness over time.

Competitive Hydrogen Production Costs: With its high efficiency and low operating costs, the HFI electrolyser can produce hydrogen at costs below $2 per kilogram, making it a competitive option for large-scale hydrogen production.

Comparison with PEM Technology

PEM electrolysers are currently considered one of the best options for green hydrogen production due to their efficiency and ability to quickly respond to variable power inputs. However, they have several drawbacks:

In contrast, the HFI AEM electrolyser circumvents these issues by using alternative, more readily available materials, and by offering superior efficiency and lower costs. This makes it a strong contender in the race to develop sustainable and economically viable hydrogen production technologies.

The HFI AEM electrolyser is poised to be a game-changer in the hydrogen industry. Its combination of high efficiency, adaptability to renewable energy, lower costs, and ease of maintenance offers a compelling alternative to existing electrolyser technologies, particularly PEM systems. As the world moves towards a greener future, technologies like the HFI AEM electrolyser will play a crucial role in making hydrogen a mainstream energy source. |